Let’s be honest: picking a supplier for something as fundamental as expanded metal mesh can feel like navigating a minefield blindfolded. You’re not just buying a product, you’re investing in the structural integrity of a project, the safety of a facility, or the aesthetic core of a design. And with a quick online search flooding you with countless Expanded Metal Mesh Manufacturers, all promising the moon, how on earth do you separate the genuine experts from the glossy brochures? It’s not just about who has the shiniest website or the loudest sales pitch. Identifying truly reliable and high-quality Expanded Metal Mesh Manufacturers is a detective game that requires looking beyond the surface, asking the right questions, and knowing where the hidden traps lie. This journey is about more than mesh, it’s about finding a partner who won’t let you down when the pressure is on.

The Foundation: It All Starts With What They Make

You can’t judge a book by its cover, and you absolutely cannot judge a manufacturer by their homepage hero image. The first real clue to uncovering top-tier Expanded Metal Mesh Manufacturers lies in the raw materials and the specifications they openly discuss.

Think about it: expanded metal mesh begins its life as a solid sheet of metal—steel, aluminum, stainless steel, you name it. The quality of that initial sheet is everything. A reputable manufacturer won’t be vague about this. They’ll specify grades: Are they using 304 or 316 stainless steel for corrosion resistance? What’s the aluminum alloy series? Is the mild steel properly galvanized? The best Expanded Metal Mesh Manufacturers treat material pedigree like a chef treats ingredient sourcing—with pride and transparency. They understand that you can’t create a durable, specification-compliant product from subpar metal, no matter how skilled the expansion process is.

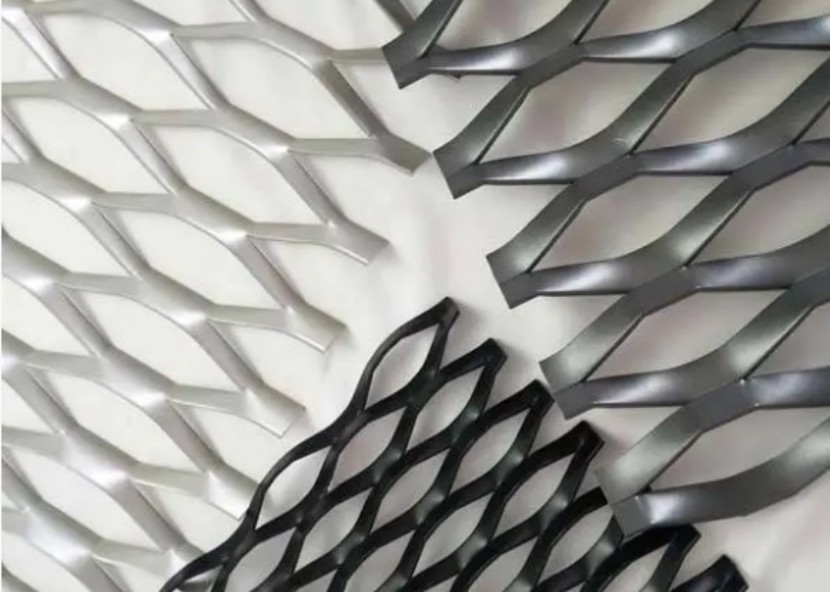

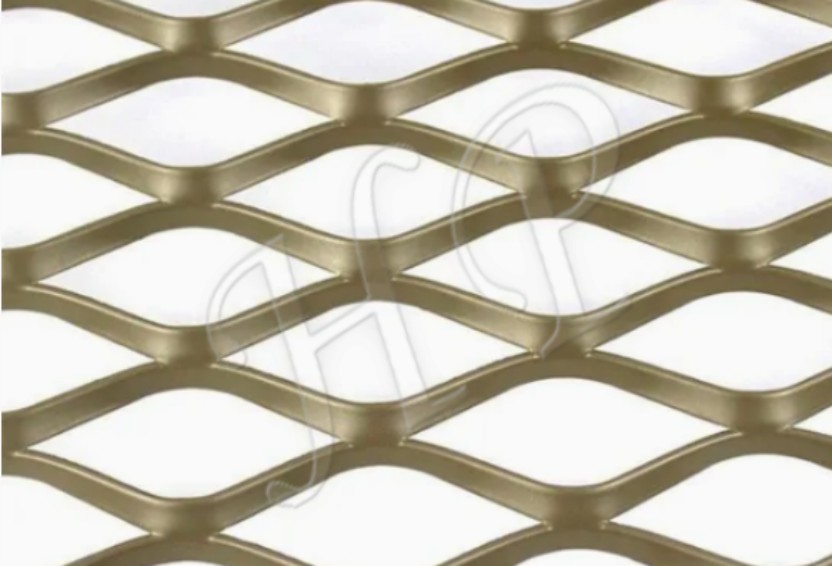

This leads directly into the heart of their craft: the expansion process itself. This isn’t just stamping out shapes, it’s a controlled, simultaneous slitting and stretching of that metal sheet. This creates a single, integrated piece with no welded joints—a key to its strength. The real skill of accomplished Expanded Metal Mesh Manufacturers shows in the consistency of the strand width, the regularity of the diamond or hexagonal pattern, and the clean, burr-free edges. Inconsistent patterns are a red flag, indicating poor tool maintenance or rushed production. The mesh should look and feel uniform across the entire sheet. This consistency isn’t just for aesthetics, it’s critical for predictable performance in filtration, screening, or load-bearing applications. When evaluating Expanded Metal Mesh Manufacturers, ask for close-up photos or even small samples from different production batches to check for this uniformity. It’s a simple test that tells a complex story about their operational discipline.

The Proof Is in the Portfolio (And the Plant)

Alright, so they talk a good game about materials and process. The next step is to see the evidence in action. The track record of Expanded Metal Mesh Manufacturers is their most convincing sales tool, but you have to know how to read it.

A diverse and detailed project portfolio is worth a thousand sales brochures. Don’t just look for pretty pictures, look for depth. Do they show mesh in a variety of applications—architectural facades, heavy-duty industrial flooring, chemical filtration screens, decorative interior features? This diversity demonstrates adaptability and a broad understanding of different client needs. It shows they can think beyond just selling a standard product. For instance, a manufacturer that has supplied mesh for a high-profile stadium walkway understands safety loads and public footfall, while one that works with pharmaceutical companies understands precision and cleanability. The most reliable Expanded Metal Mesh Manufacturers will have case studies that explain the challenge and how their mesh solution met it. This context is golden.

If you have the opportunity, a factory visit is the ultimate litmus test. You’re looking for organization, technology, and attitude. Are the production floors clean and organized? Are the expansion presses and ancillary equipment (like flattening or rolling machines) well-maintained? Modern Expanded Metal Mesh Manufacturers often employ CNC-controlled machinery for incredible precision, especially for custom patterns. But also, talk to the people. The pride (or lack thereof) that floor managers and operators take in their work is palpable. Do they have a dedicated quality control station with measuring instruments? Are finished products stored properly to prevent damage? A visit tells you if they are a slick sales front with a chaotic backend or a genuinely engineered-focused operation. It reveals the culture behind the Expanded Metal Mesh Manufacturers you’re considering.

Communication is Your Compass

Here’s where many seemingly good choices fall apart. The technical capability might be there, but if the communication is poor, your project is heading for trouble. The interaction you have with potential Expanded Metal Mesh Manufacturers during the quoting and inquiry phase is a preview of your entire working relationship.

Pay close attention to the questions they ask you. If a manufacturer just quotes a price based on your basic dimensions and material request, be wary. The truly reliable ones will interrogate your project. They’ll ask about the application’s environment (indoor/outdoor, chemical exposure, temperature extremes), the required load-bearing capacity, desired aesthetics, installation method, and any relevant industry standards (ASTM, ISO, etc.). This proactive questioning shows they are engineering partners, not just order-takers. They are trying to ensure the mesh they supply performs perfectly in your specific use case, potentially saving you from a costly mismatch.

Furthermore, assess their responsiveness and clarity. Do they explain technical details in a way you can understand? Are they upfront about lead times, even if they’re long? Can they provide clear, detailed drawings before production? Transparency during communication is a strong indicator of integrity. If they are evasive about production schedules, costs, or capabilities at this early stage, it will only get worse later. The best Expanded Metal Mesh Manufacturers view clear, consistent communication as a core part of their quality guarantee. They know a miscommunication on a custom mesh order can lead to a useless product arriving at your dock, wasting everyone’s time and money.

Decoding the Hidden Value Signals

Sometimes, the difference between an average supplier and an exceptional one lies in the extra services and the subtle signs of commitment. When comparing Expanded Metal Mesh Manufacturers, look for these value-added indicators.

First, consider their support around the core product. Do they offer comprehensive post-expansion processing? The ability to precisely level or flatten mesh, apply coatings (powder coating, PVC dip, galvanizing), shear it to exact tolerances, or even roll it into cylinders is huge. A manufacturer that can provide these services in-house offers better quality control, shorter overall lead times, and single-point accountability. It’s far more efficient than shipping raw mesh to a third-party processor and hoping for the best.

Secondly, evaluate their logistical and packaging competence. How do they protect their product for shipment? Proper packaging, with edge protection and robust crating for large orders, prevents damage in transit—a surprisingly common issue with delicate mesh profiles. Reliable Expanded Metal Mesh Manufacturers have this down to a science. Also, their experience with international export documentation, customs, and freight can be a lifesaver if you’re sourcing globally. They should guide you through the process, not leave you to figure it out.

Finally, don’t underestimate the power of certifications and industry recognition. While not the only measure, certifications like ISO 9001 for quality management systems demonstrate a formal commitment to consistent processes and continuous improvement. Membership in relevant industry associations shows they are networked and engaged with the latest standards and trends. These are signals that the manufacturer invests in their own business infrastructure for the long haul, which translates directly into reliability for you.

In the end, finding world-class Expanded Metal Mesh Manufacturers is a process of diligent investigation. It’s about peering behind the marketing curtain to assess material mastery, verifying capability through proven projects, establishing a partnership through clear communication, and recognizing the value of full-service support. It takes more time upfront than just clicking on the cheapest quote, but the payoff is a seamless project, a product that performs as expected for years, and, perhaps most importantly, a lot fewer headaches. Your mesh should be the solution, not the problem, and it all starts with choosing the right hands to make it.